In this advantageous market environment, one of our customers, the Swiss hemp breeding company Puregene, is spreading its wings 2. The company was founded in 2017 by ETH Zurich alumni and offers one of the most sophisticated cannabis genomics-based, speed-breeding programs available today using trait discovery and genomic selection. Puregene’s internationally located customers, some of them pharmaceutical companies, can profit from customized plant varieties which fit their specific required medicinal purpose, thereby giving them a competitive edge in today’s fast evolving cannabis market.

The high-quality product Puregene is offering, is heavily sought after including in the US. The company has been working closely with the US Nursery LLC and US regulatory bodies to pave the way for importing live hemp plants and seeds. In September 2019 the first live Cannabis sativa (industrial hemp) plants were legally imported to the US from Switzerland and condition-monitored using Modum’s MODsense One monitoring solution. This intercontinental shipment of the live plants was a groundbreaking achievement for the growing industrial hemp industry, by opening borders for international trade and smoothing the way for future imports through the proper legal channels.

Delicate Seedlings

Live plants of any species are highly sensitive to the environmental conditions they are kept in and young seedlings even more so. During the “black box” of air freight, temperature and humidity can fluctuate significantly. Typically, in vitro plants and seeds need to be kept at room temperatures and unrooted clones need to be refrigerated to maintain the highest quality product for the end customer.

When evaluating the first deliveries, Puregene was faced with a high mortality rate of live plants shipped to the US. This drove Puregene’s Lead Technology Manager Dr. Gavin George to look for ways to gain actionable insights of the conditions the plants are exposed to when in transit: “At Puregene we work every day to reduce uncertainty using the most advanced technologies. Whether it be in the process of breeding, variety development, or transport of plants to our distribution partners, optimization requires volumes of accurate data.”

Partnering with the Best

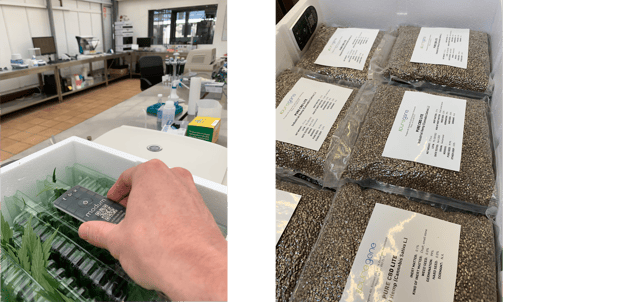

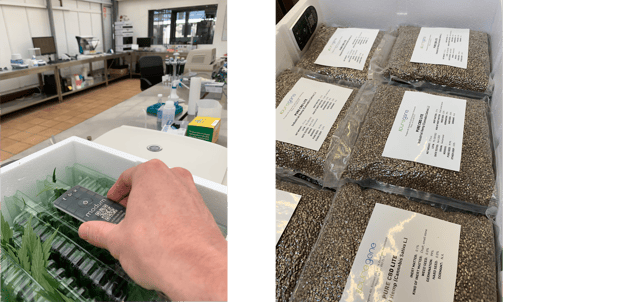

While looking for a reliable partner with expertise in not only supply chain monitoring but also in optimization and emerging technologies, Gavin found Modum. The MODsense One solution 3, with its hassle-free set up was quickly integrated into Puregene’s packaging and shipment process. On the Puregene side in Switzerland, the shipment’s condition profile was set up and transferred wirelessly to the MODsense T data logger, which was added to the shipment. On the receiving end in the US, Puregene’s customer US Nursery LLC, simply reads out the monitoring data on the package upon arrival, with a mobile phone requiring no training whatsoever. Since MODsense One is deviation driven, Puregene’s quality control personnel only needed to investigate shipments if they received an alert, compliant shipments were automatically released. The data-driven and autonomous quality control feature provided both peace of mind, as well as valuable time savings. This high level of simplicity is what convinced Gavin to use the awards-winning monitoring solution.

“This is why I love Modum’s monitoring solution, which not only tracks the critical temperatures of our shipments but also how long they take to complete and whether the packages have been tampered with – all critical information if you are shipping live, valuable and regulated plant material.”

Improving through Data

Based on the actionable data collected in transit, Puregene was able to improve the ways they control temperature and humidity by optimizing packaging – which resulted in decreased mortality rates of the live hemp – a real value-add for the company. Gavin added, that “Gaining reliable data driven insights on shipping temperatures and time was essential for the continuing optimization of our shipments.”

Are you shipping sensitive goods and need a reliable and hassle-free monitoring solution? Talk to us, and together we will find the solution that fits your needs.

1 https://www.fortunebusinessinsights.com/industry-reports/cannabis-marijuana-market-100219

2 https://www.puregene.com/

3 https://modum.io/solutions/modsense-one