Back in the early 2000s, Starbucks’ business was starting to gain momentum but their supply chain and logistics teams were struggling to keep up. The famous coffee business quickly realized that they needed to put strategies and technologies in place to master the movement of their ingredients, materials and products.

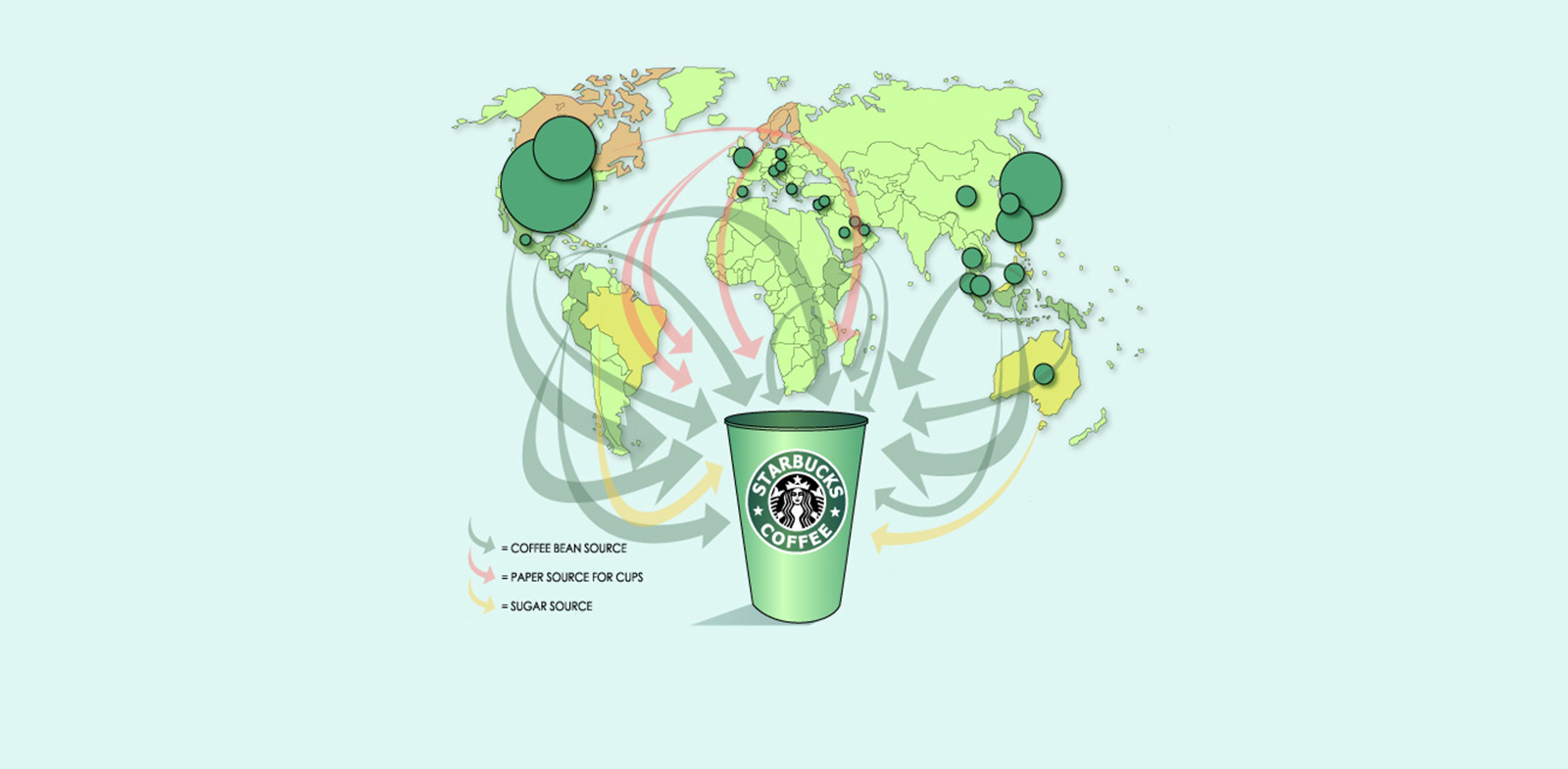

By making use of a vertically-integrated supply chain, the company is involved in every step of the process, as coffee beans move from farms to the cup of coffee that is ultimately sold to consumers. Last year, Starbucks announced that they were working with Microsoft to develop a blockchain-enabled supply chain tracking system that pairs with a mobile app and allows customers to track the journey of the beans they buy and the coffee they drink.2 This Azure-based blockchain service creates a transparent electronic ledger that supply chain participants can use to input transactional data.

Not only does this kind of thing improve coffee supply chain scrutiny, it also secures better incomes for farming communities.

What can we learn from Starbucks?

It comes down to one thing – transparency.

In fact, in March 2019, the coffee giant announced their “digital transparency plan”, which aims to verify that their coffee beans as 100% ethically and sustainably sourced. The initiative traces the genesis of beans from around 380 000 coffee farms and shares this information with customers.

Smart tracking is an essential part of this transparency push. By using these connected tracking solutions, Starbucks can identify supply chain inefficiencies, reduce costs, eliminate errors, improve performance and, ultimately, increase profit margins. It’s all about mastering how to move ingredients, materials and products as affordably as possible.

But they’re not the only ones doing this kind of thing. According to Gartner, more than half of new business processes will incorporate some element of the Internet of Things (IoT) in 2020. W. Roy Schulte, VP and distinguished analyst at Gartner, explained back in 2016 3:

"Uses of the IoT that were previously impractical will increasingly become practical. The IoT is relevant in virtually every industry, although not in every application. There will be no purely 'IoT applications.' Rather, there will be many applications that leverage the IoT in some small or large aspect of their work.”

In line with this, McKinsey & Co predicts that the IoT will have a total potential economic impact of anywhere from $3.9 trillion to $11.1 trillion a year by 2025.4

Smart sensors and IoT-enabled tracking devices will be attached to everything from individual products and crates to shipping containers. These connected technologies will be embedded throughout manufacturing facilities and warehouses and will aid the tracking of entire transportation fleets. In the case of agricultural products, like coffee, which are especially susceptible to delays, which can have an adverse impact on the quality of the product. As such, is critical to be able to monitor temperature variations and other environmental factors as these items move from farms to processing facilities and on to distribution centers to supermarkets and restaurants.

Over the last years, being able to verify product authenticity and trace the source of products has become hugely important. This is especially true as producers and regulators place greater emphasis on tackling counterfeit goods and as they champion supply chain sustainability. Emerging technologies enable this visibility.5

Our future is smart, it’s connected and it’s driven by innovative, emerging technologies. Are you ready? Chat to us today to find a supply chain solution that meets your unique supply chain needs.

1 https://www.thebalancesmb.com/how-starbucks-changed-supply-chain-management-4156894

2 https://www.computerworld.com/article/3393211/from-coffee-bean-to-cup-starbucks-brews-a-blockchain-based-supply-chain-with-microsoft.html

3 https://www.gartner.com/en/newsroom/press-releases/2016-01-14-gartner-says-by-2020-more-than-half-of-major-new-business-processes-and-systems-will-incorporate-some-element-of-the-internet-of-things

4 http://www.mckinsey.com/business-functions/business-technology/our-insights/the-internet-of-things-the-value-of-digitizing-the-physical-world

5 https://modum.io/news/provenance-transparency-chain

Image Source: https://www.princeton.edu/~ina/infographics/starbucks.html